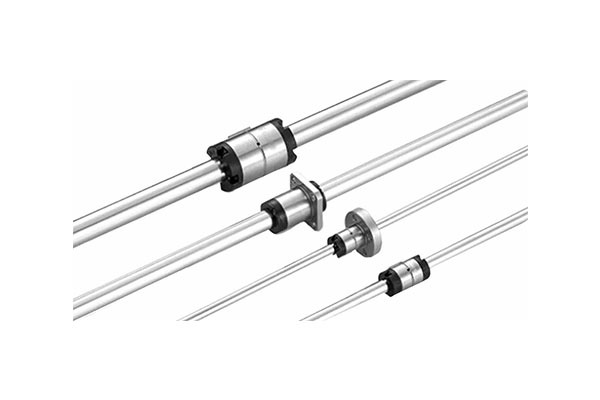

Ball Spline

Keywords : SummitSteel

Classification :

PRODUCT DETAILS

Ball splines utilize balls mounted within the outer cylinder of a spline shaft, rolling smoothly and transmitting torque simultaneously within precision-ground rolling grooves. Their unique contact point design offers a wide contact angle (40°), resulting in high sensitivity and significantly increased load-carrying capacity. They are particularly effective in environments subject to excessive vibration and shock loads, demanding high positioning accuracy, and requiring high-speed motion. Furthermore, even when used in place of linear ball bushings, ball splines offer a load rating more than ten times that of linear bushings for the same shaft diameter, enabling a very compact design. They also offer safe operation and high durability, even under cantilever loads and torque.

Ball Key Structure

Ball splines are available in four types: round flange SLF, cylindrical SLT, square flange SOF, and cylindrical SOT. Depending on the shaft diameter, the ball contact path is further divided into two-row (180°) (SLF/SLT 6-20), (SOT/SOF 8-25), and four-row (70°) (SLF/SLT 25-50). Hollow shafts are also available.

Advantages

Large Load Capacity

The ball rolling grooves are precision-ground and form, and utilize a Gothic-type 40° contact angle. This large contact angle provides high load capacity in both radial and torque directions.

Zero Backlash in Rotation

By employing two to four opposing rows of balls with a 40° contact angle, the spline shaft and spline outer cylinder are connected. Zero backlash in rotation can be achieved by adjusting the preload.

High Sensitivity

The special design of the ball contact point not only provides high rigidity but also enhanced sensitivity, reducing energy waste.

High Rigidity

The large contact angle provides high rigidity, and the ability to apply appropriate preload allows for high torque and moment stiffness.

Easy Assembly

The special design ensures that the balls remain even when the splined outer cylinder is removed from the splined shaft. This makes assembly, maintenance, and inspection easy.

Product Specifications

The SL series is available in two types: ready-to-assemble and single-piece. While both offer the same specifications and dimensions, the key difference is that the ready-to-assemble model is manufactured by our factory, with the spline shaft cut and assembled with the spline cylinder according to customer order. This assembly achieves precision-grade accuracy. The single-piece model, on the other hand, ships the spline shaft and spline cylinder separately, offering greater convenience. However, the assembly accuracy is not as high as it could be. However, strict quality control is maintained throughout the manufacturing process, resulting in world-class precision and ease of assembly. Customers can conveniently prepare and assemble the product themselves.

PACKAGING AND DELIVERY

The company's internal technical personnel account for more than 60% of the total number of employees. There are a group of experts who have been engaged in this industry for a long time and young and promising technical talents. Many new products have obtained national patents and won the honor of the National Invention Award.

APPLICATION AREAS

Aerospace

Car

Semiconductor

Electronic Devices

Testing Equipment

Industrial Robots

FAQ

Q:Does the product have quality inspection before loading?

Q:Can l go to your factory to visit?

Q:How many countries you already exported to?

Q:How long does your delivery time take?

Q:What product information do l need to provide?

Q:Can you send samples?

RELATED PRODUCTS

GET A FREE QUOTE